Dimension | Liquid Ring Compressor | Centrifugal Compressor | Reciprocating Compressor |

Isothermal Compression | (Prevents gas decomposition) | ❌ High ΔT (50~150°C) (Explosion risk) | ❌Moderate ΔT (30~100°C) (Requires energy-intensive cooling) |

Liquid/Solid Tolerance | ✅ Handles liquids/solids (Non-metallic, corrosion-proof) | ❌Strictly gas-only (Impeller erosion risk) | ❌ Limited solid tolerance (Valve/piston damage) |

Structural Simplicity | ✅ Single moving part (Oil-free, low maintenance) | ❌ High-speed Impeller and complex seals/lubrication | ❌ Multiple moving parts (Frequent maintenance) |

Safety & Eco-Compliance | ✅ Oil-free + low-temp design (Zero contamination) | ❌ Oil leakage risk (Requires enhanced anti-explosion design) | ❌ High lubricant consumption (Media pollution, separation required) |

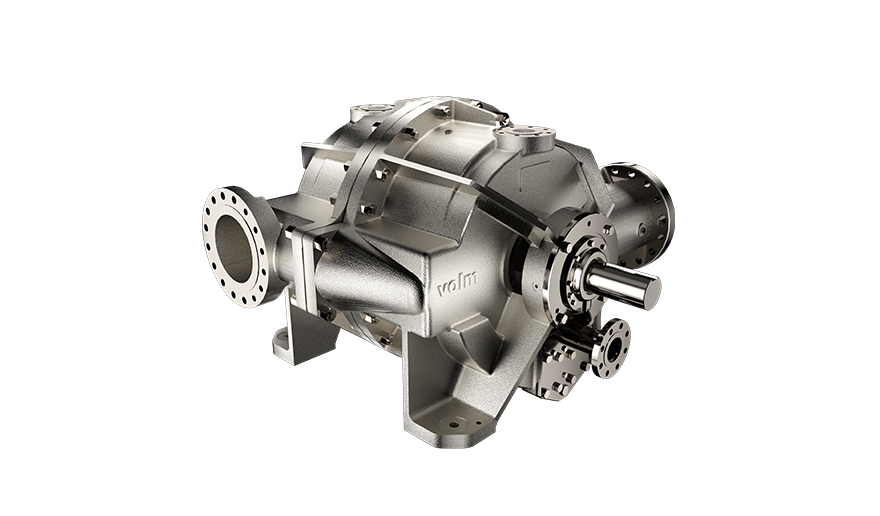

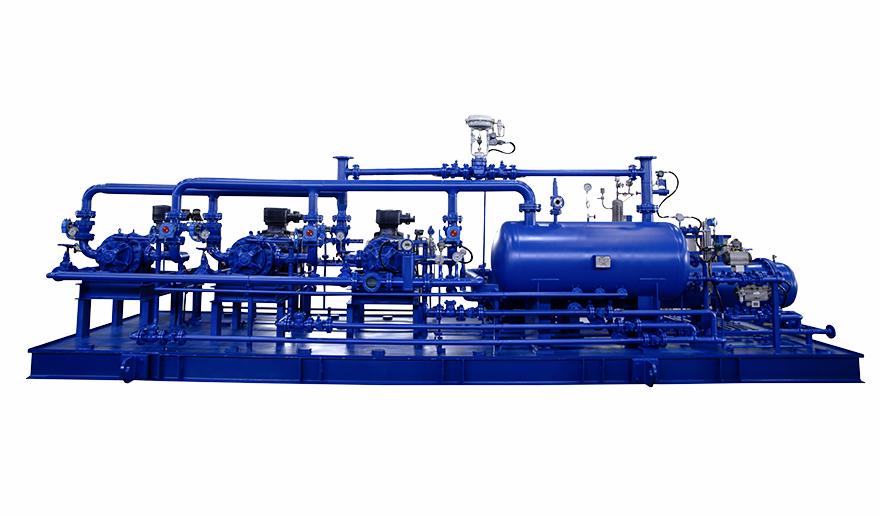

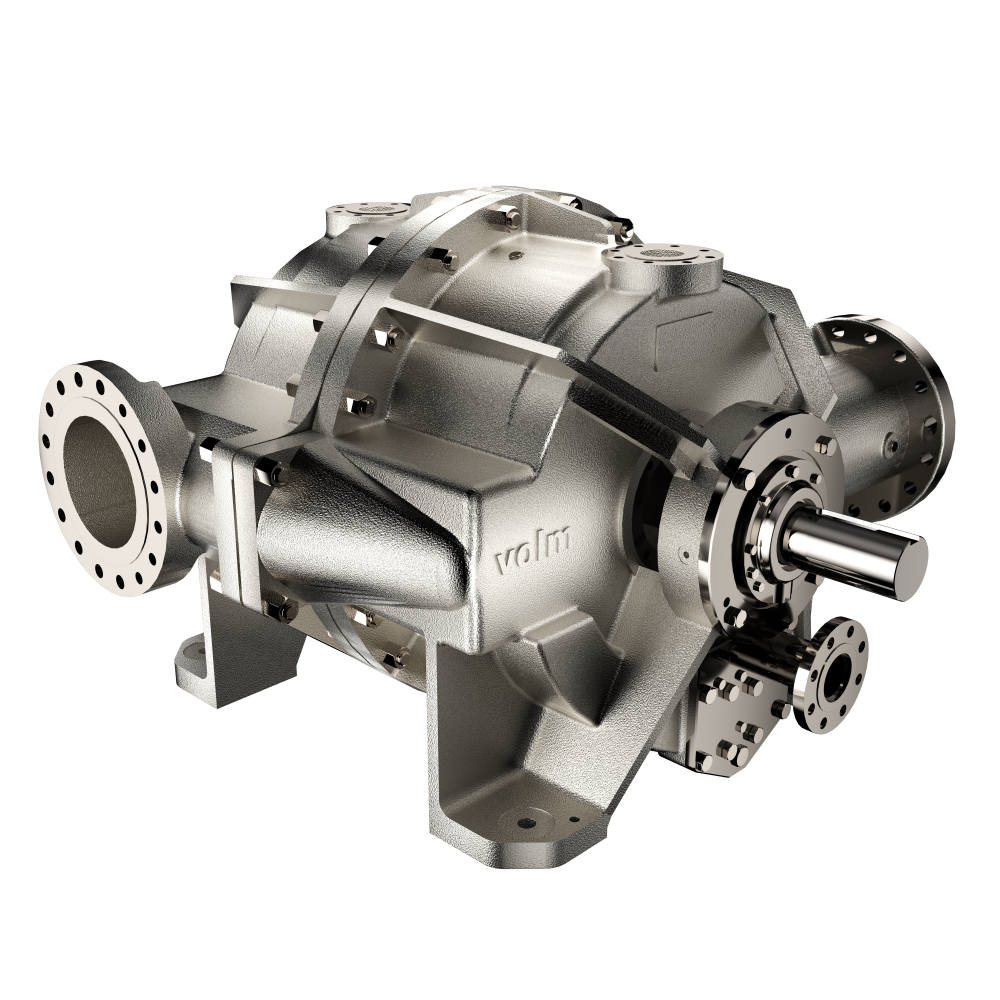

Centrifugal/reciprocating compressors proved unsuitable for acrylonitrile gas. Volm’s liquid ring technology excels in safety and adaptability.