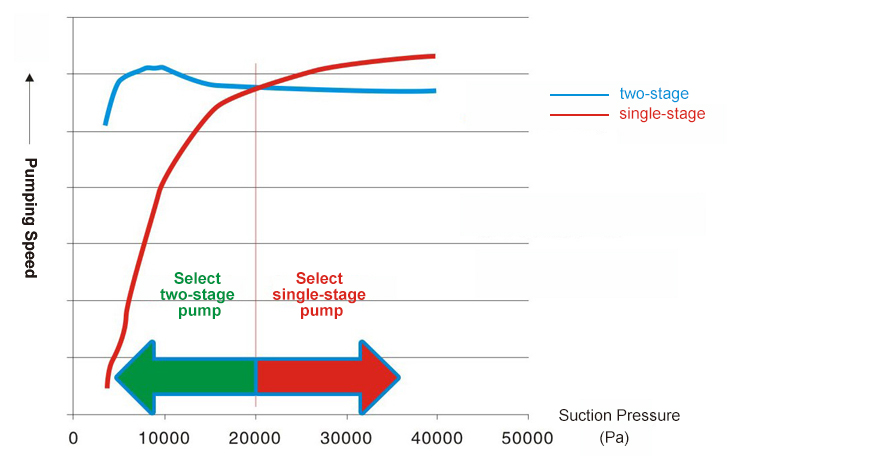

1.Efficiency Drop in High Vacuum

Single-stage pumps exhibit plummeting pumping speeds and surging energy consumption when operating below 20 kPa(A), failing to meet high-flow requirements for drying processes. In contrast, two-stage pumps’ efficiency in high-vacuum operations exceeds single-stage pumps by 35~40%, with proportionally lower energy consumption. Selecting vacuum pumps tailored to specific operating conditions is therefore essential for cost-effective operation.

Remarks: working liquid is 20℃ water, and atmospheric pressure is 101.3kPa.

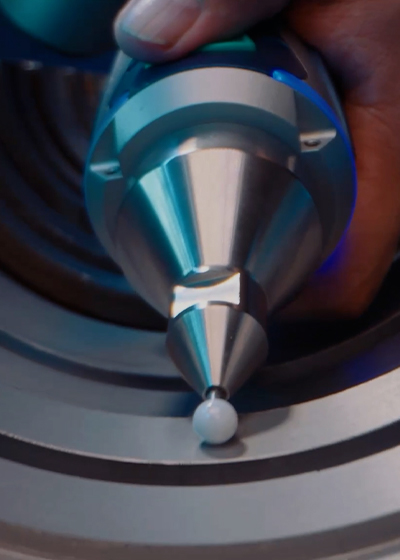

2.Particle Clogging Risks

Residual vinyl chloride monomer particles (50~100μm) may clog liquid circuits, triggering unplanned downtime.

3.High-Pressure Sealing Challenges

Barrier fluid suction pressure for double mechanical seals reaches 0.7 MPa. Manual pressure regulation risks seal failure and leakage.